„THE RESULT IS THE GOAL”

To assure the high quality and performance from idea to a product we follow the safe quality standards for the entire project. Therefore, the customers’ expectations will be not only reached but exceeded.

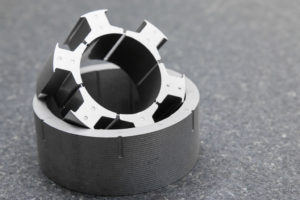

We will never tireless on pointing that a product will be only successful if the expectations of the end consumer will be fulfilled. Behind this exists a secure quality policy of every new project. Surveillance of the quality of processes and measurement technology on the top level secure our customers the agreed specification. More than 20 years knowledge in the production of the magnets and magnet systems make possible early recognizing of problems and fruitful realization of the project.

Highly competent and motivated employees ensure that our customers will get the best service during project beginning and order for the run production.

We do not only aim for control of the quality from the produced parts but we live quality and we see every employee as an important fragment from quality assurance process.

Quality experienced and engineered in Germany

Deutsch

Deutsch