Rare earth permanent magnets are metallic permanent magnets. In certain applications the eddy currents in combination with high degaussing fields can cause irreversible losses of a permanent magnet.

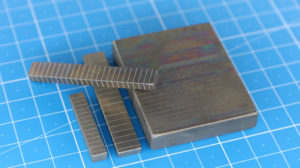

One option for preventing this is to partition the magnets and bond these partitions in an electrically isolated environment. We call this technology “sliced magnet technology”. Meanwhile the individual segments are not only glued together, but also electrically isolated by adding so-called spacers.

Specially shaped mounting fixtures make it possible, that the newly jointed magnet can be grinded to size and therefore reach tight tolerance specifications.

If required the magnet can be protected against corrosion. Here we recommend the use of a cathodic dip paint (KTL) or our PASSAL®-coating, which makes working temperatures over 200°C possible.

Customary shapes for „sliced magnets“ are bars and segments. We have the ability to calculate the optimal size of segmentation for you, depending on the drive, the application and the material.

Deutsch

Deutsch