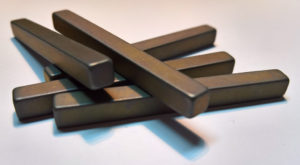

Hard ferrites are ceramic permanent magnets based on the (chemical) compounds BaFe12O19 oder SrFe12O19.

On a quantity basis they are the most produced permanent magnets world-wide by now. The main advantages are low costs of material, high chemical stability and low electrical conductivity. The production technique is powder-metallurgical, which, in contrast to NdFeB magnets, occurs in open atmosphere.

We differentiate between following material grades:

Isotropic hard ferrits:

They are pressed from drying powder or wet particles (mud) without applying a field of magnetic orientation. As a result the magnets reach very low remanences (up to about 250 mT) and energy densities (up to about 12 kJ/m3).

Anisotropic hard ferrites

They are also produced from drying powder or wet particles, but this time they are pressed into designated moulds under the influence of a field of magnetic orientation. Remanence reaches values between about 440mT, and energy densities up to about 40 kJ/m3 respectively. Since coercivity of this kind of hard ferrites is greatly reduced at low temperatures it is necessary to mind for adequate dimensioning, and moreover the right choice of ferrite grade, if final application is to be at low temperatures.

[ngg src=”galleries” ids=”6″ display=”pro_horizontal_filmstrip”]

Deutsch

Deutsch